GRP Water Tank Setup in the Philippines: How On-Site Installation Really Works

Across the Philippines, industries from agriculture to municipal water systems are seeking reliable, corrosion-resistant, and long-lasting Water Storage solutions.

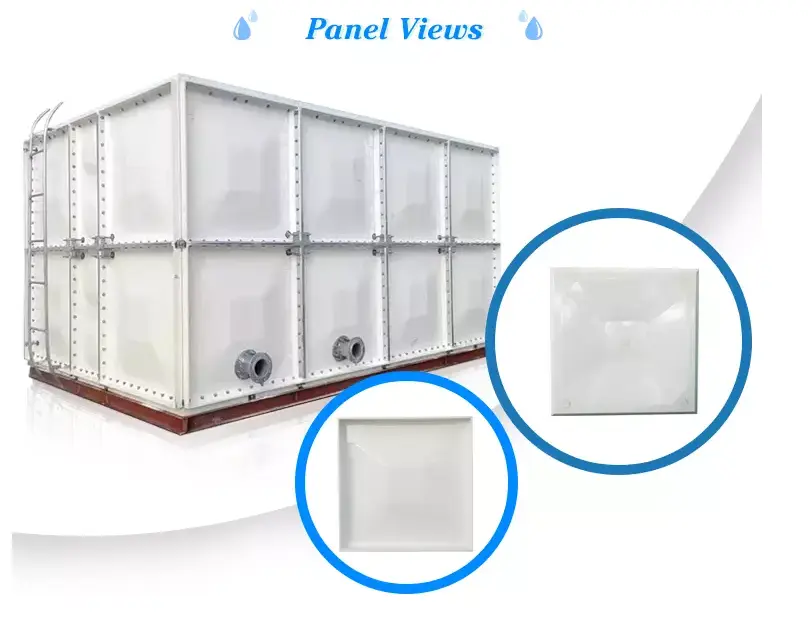

GRP (Glass Reinforced Plastic) Water Tanks have become a preferred option because of their modular design, durability in tropical climates, and adaptability in both rural and urban projects.

But one question always comes up for contractors, distributors, and water project managers:

👉 How does GRP tank installation work on-site?

Let’s walk through the process step by step—so that pump suppliers, fire protection companies, irrigation firms, water authorities, purifier dealers, and pipe distributors in the Philippines can understand and apply it directly.

Step 1: Site Preparation Before Tank Delivery

A GRP tank installation starts before the tank even arrives. Local project teams need to:

-

Survey the site – Check soil conditions, ground stability, and accessibility.

-

Lay a proper foundation – Usually a concrete pad or steel beams that ensure load-bearing stability.

-

Verify clearances – Adequate space for panel assembly, maintenance access, and piping connections.

💡 In humid, flood-prone Philippine regions, foundations must be raised or reinforced to prevent waterlogging and settlement.

Step 2: Modular Panels and Accessories Arrive

Grp Water Tanks are shipped asflat-packed modular panels, making transport easier across the Philippine islands.

Along with the panels come:

-

Internal tie-rods and supports

-

Sealing materials (food-grade rubber gaskets)

-

Bolts, nuts, and washers

-

Inlet/outlet pipe fittings

This modular system reduces logistics costs, especially in rural provinces or remote island projects—where moving a one-piece steel tank would be impossible.

Step 3: Assembly Process on Site

Once the materials are on location, trained technicians begin the assembly:

-

Base panels installed on the prepared foundation.

-

Wall panels added layer by layer, bolted with sealing gaskets to prevent leaks.

-

Internal bracing fixed with tie-rods and reinforcements for strength.

-

Roof panels mounted, often with manholes or hatches for inspection.

⚙️ Unlike welded steel tanks, this process requires no heavy welding equipment, making GRP tanks far more practical for provincial areas with limited infrastructure.

Step 4: Plumbing and Connections

After structural assembly, installation teams connect the tank to:

-

Inlet pipes – From pumps, boreholes, or municipal mains.

-

Outlet pipes – Feeding fire systems, irrigation, or household supply.

-

Overflow and drainage – Prevents flooding during overfilling.

-

Manholes – For inspection and cleaning.

Proper sealing at connection points is critical in the Philippines, where fluctuating water pressures and typhoon-heavy rains can strain weak joints.

Step 5: Testing and Commissioning

Before handover, technicians perform:

-

Leak tests – Partially fill the tank and check for seepage.

-

Structural checks – Verify bracing and bolts hold under load.

-

Operational tests – Confirm inlet/outlet flow performance.

Only after these tests pass is the GRP water tank officially commissioned for use.

Why GRP Tanks Are Ideal for the Philippines

-

✅ Corrosion resistance – Handles coastal air and saline conditions better than steel.

-

✅ Lightweight panels – Easy to ship between islands.

-

✅ Flexible capacity – From small village supply to city-scale storage.

-

✅ Low maintenance – No repainting, less frequent cleaning than steel tanks.

For agriculture, firefighting, and water treatment industries, GRP tanks are the most cost-effective choice long-term.

The installation of a GRP water tank in the Philippines is straightforward yet precise:

-

Prepare the foundation

-

Assemble modular panels

-

Connect inlet/outlet systems

-

Test thoroughly

With the right planning, GRP tanks deliver decades of reliable service—even under harsh tropical weather conditions.

FAQs: GRP Water Tank Installation in the Philippines

1. How long does GRP tank installation usually take?

Most mid-sized tanks (50–200 m³) take around 5–7 days, depending on site conditions and weather.

2. Do GRP tanks need repainting like steel tanks?

No. GRP is naturally corrosion-resistant and does not require anti-rust coatings.

3. Can GRP tanks handle salty or coastal water in the Philippines?

Yes. GRP is resistant to saltwater corrosion, making it ideal for coastal provinces.

4. What kind of maintenance do GRP tanks need?

Only basic cleaning and inspection every 6–12 months is usually enough.