Pressed Steel Tanks have emerged as a popular solution in various industries for their durability, efficiency, and cost-effectiveness. According to a recent report by the Global Market Insights, the pressed steel tank market is expected to witness substantial growth, driven by the increasing demand for economical storage solutions in sectors such as water treatment, municipal services, and agriculture. As industries aim to optimize their operations, the introduction of pressed steel tanks provides a practical alternative to traditional storage methods, offering both environmental and financial benefits.

The unique properties of pressed steel tanks, such as enhanced strength-to-weight ratios and resistance to corrosion, position them as a highly effective storage solution for liquids and materials. Furthermore, data from the Water Environment Federation suggests that the adoption of pressed steel tanks in water management systems can lead to improved resource utilization and reduction in maintenance costs, which are crucial factors for municipalities striving to enhance service delivery.

With the ongoing advancements in manufacturing techniques and materials technology, pressed steel tanks are making significant inroads into various applications, including industrial, agricultural, and urban infrastructure. As industries continue to prioritize sustainability and reliability in their operations, pressed steel tanks stand out as a viable option that can meet the evolving demands of the market.

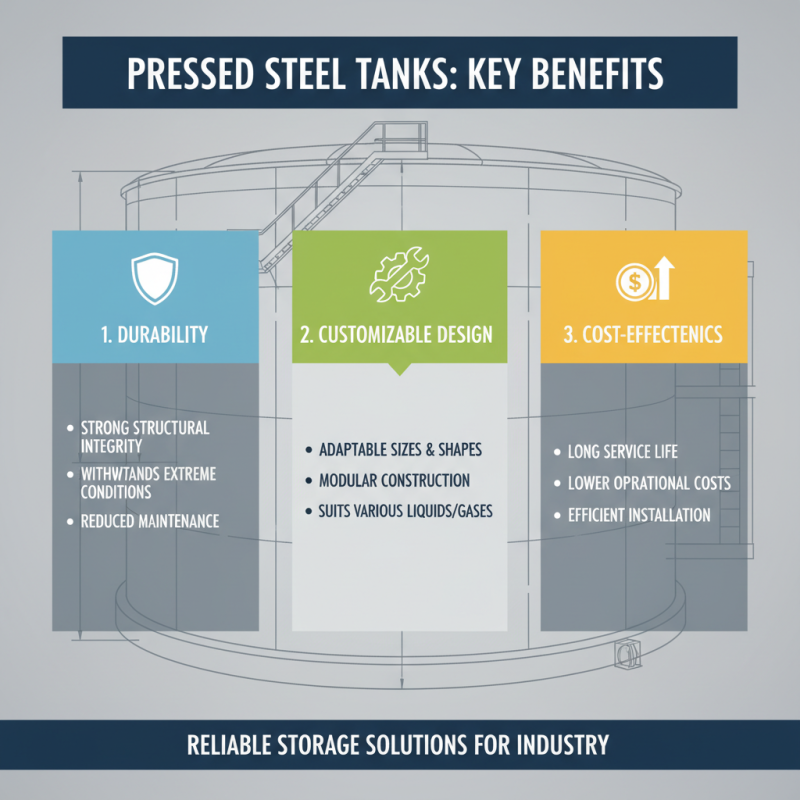

Pressed steel tanks offer a host of benefits across various industries, primarily due to their durability, customized design options, and cost-effectiveness. One of the key advantages is their strong structural integrity. These tanks can withstand extreme conditions, including harsh weather and fluctuating temperatures, making them ideal for storing a variety of liquids and gases. Their robust construction reduces maintenance needs, ensuring that companies can focus on their core operations without worrying about tank failures or leaks.

Moreover, pressed steel tanks are highly versatile in their applications. They are widely used in industries such as water treatment, agriculture, and manufacturing, where large volumes of water or other liquids are required. In agriculture, for instance, they serve as effective storage solutions for irrigation water or fertilizers, while in water treatment facilities, they help manage the storage and distribution of clean water. The adaptability of pressed steel tanks means they can be tailored to meet specific storage requirements, whether it involves adjusting size, capacity, or additional features like insulation, further enhancing their utility across different sectors.

Pressed steel tanks come in various types, each designed to cater to specific needs and applications. One common type is the vertical cylindrical tank, which is ideal for storing large quantities of liquids, such as water or chemicals. Its height allows for a compact footprint, making it suitable for installations where space is limited. These tanks are typically equipped with smooth inner surfaces that help in preventing sediment buildup and facilitate easy cleaning.

Another popular option is the horizontal tank, which offers a different set of advantages. These tanks are often used for transportation and can easily be installed in areas where vertical space is limited. Their design allows for more straightforward access for maintenance and inspection. Furthermore, pressed steel tanks often come with custom features such as insulation layers or coatings for enhanced protection against corrosion, ensuring longevity and reliability in various environmental conditions. Such unique features make them versatile and adaptable for numerous industrial and commercial applications.

Pressed steel tanks have become a popular choice for various storage solutions due to their durability, cost-effectiveness, and versatility. These tanks are primarily used in industries that require secure and robust storage for liquids, such as water, chemicals, and fuel. Their structural strength allows them to withstand high pressure and environmental stresses, making them suitable for both above-ground and underground applications. The ability to customize sizes and shapes further enhances their functionality, enabling businesses to optimize space and efficiency in their storage systems.

In agricultural settings, pressed steel tanks are often utilized for water storage and irrigation systems, providing a reliable source of water for crops and livestock. Moreover, in industrial contexts, these tanks can serve as effective solutions for storing hazardous materials, ensuring compliance with safety regulations while preventing leaks and contamination. Additionally, their resistance to corrosion and wear makes them ideal for long-term use in various environmental conditions. Overall, the versatility of pressed steel tanks makes them an essential component in modern storage solutions across multiple industries.

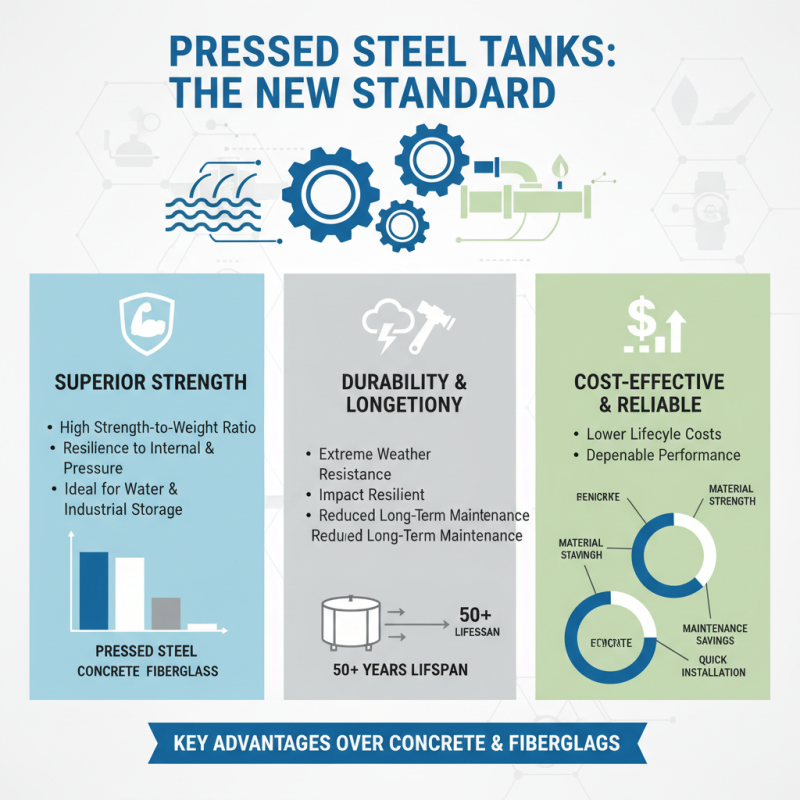

Pressed steel tanks offer a range of comparative advantages over traditional materials such as concrete and fiberglass. Firstly, their strength-to-weight ratio is noteworthy. According to industry reports, pressed steel tanks can withstand both internal and external pressure more effectively than many alternatives, making them ideal for various applications, including water storage and industrial processes. Their resilience to extreme weather conditions and physical impacts ensures longevity and reliability, which are critical factors in reducing long-term maintenance costs.

Additionally, pressed steel tanks have the benefit of being highly customizable. They can be fabricated to meet specific diameter, height, and capacity requirements, providing versatility for different projects. Furthermore, pressed steel has a lower initial cost compared to fiberglass, often proving to be a more economical choice for large-scale installations. Industry analysis indicates that the lifecycle cost of pressed steel tanks can be 20% lower than that of their fiberglass counterparts, especially when considering their durability and lower repair frequency.

Tips: When selecting a tank for your project, consider not just the initial purchase price but also the durability and maintenance costs associated with different materials. Investing in pressed steel can result in savings over the lifespan of the tank. Additionally, ensure that any tank you choose complies with local regulations, as this can greatly affect operational efficiency and environmental safety.

Pressed steel tanks are known for their robustness and long service life, but like all structures, they require regular maintenance to ensure optimal performance. The maintenance regimen typically includes inspecting for corrosion, checking joints and welds, and monitoring the tank's foundation. Regular cleaning is also essential to prevent sediment buildup, which can affect water quality and tank integrity. By adhering to a consistent maintenance schedule and addressing any issues promptly, the lifespan of pressed steel tanks can be significantly extended, often reaching up to several decades.

Tips for maintaining pressed steel tanks include creating a maintenance checklist that outlines inspection frequencies and tasks, implementing a corrosion protection strategy such as coatings or cathodic protection, and documenting all maintenance activities to track the condition over time. It's also advisable to keep the tank's environment in mind; preventing debris accumulation around the tank can help maintain its overall health. Furthermore, engaging with professionals for periodic assessments can ensure that your tank remains in prime condition, thus safeguarding the investment made into these durable structures.