In recent years, the adoption of Modular Water Tanks has seen exponential growth due to their versatility and efficiency in various applications. According to a report by the Global Water Resources Institute, the global market for modular water storage solutions is projected to reach $1.2 billion by 2025, emphasizing the increasing demand for sustainable water management systems. As the importance of adequate water storage continues to rise, understanding the intricacies of modular systems becomes essential for both end-users and industry professionals.

Water storage expert Dr. Emily Chen states, "Modular Water Tanks offer unparalleled flexibility and scalability, making them a preferred choice for various sectors, including agriculture, municipal services, and emergency response." This highlights the significant role that such systems play in ensuring a reliable water supply, especially in regions prone to drought or infrastructural challenges.

Choosing and maintaining your Modular Water Tanks effectively can enhance water quality and longevity, ultimately ensuring that they serve as a reliable source for communities and businesses alike. In this article, we will explore ten essential tips that will help you make informed decisions about selecting and caring for your modular system, thereby maximizing its utility and lifespan.

When selecting modular water tanks, it's crucial to understand the various types available in today's market. Primarily, modular water tanks can be categorized into several designs, including plastic, fiberglass, and metal tanks. According to the Water and Wastewater Equipment Manufacturers Association (WWEMA), modular tanks made from polyethylene are preferred for their lightweight and corrosion-resistant properties, making them ideal for residential and commercial applications. In contrast, fiberglass tanks offer durability and resistance to chemical leaks, which is beneficial for industrial uses.

In recent years, the demand for modular water tanks has surged, driven by the growing emphasis on water conservation and sustainable practices. A report by the International Water Association (IWA) indicates that modular tanks contribute to efficient water management systems, reducing waste by facilitating rainwater harvesting and greywater recycling. Consequently, modular tanks are becoming essential components in urban planning and environmental stewardship initiatives.

It's essential to consider factors such as capacity, installation requirements, and maintenance needs when choosing the appropriate type for specific applications.

When it comes to selecting a modular water tank system, evaluating capacity requirements is a crucial step that significantly influences your decision. It's essential to assess your specific water storage needs based on factors such as usage frequency, the number of occupants, and the purpose of the water being stored, whether for irrigation, household use, or industrial applications. Consider potential fluctuations in demand during peak usage times to ensure your system can handle the maximum requirement without overextension.

Additionally, understanding the dimensions and layout of your installation site will directly impact the sizing of your modular tanks. Modular systems can be tailored to fit various spaces, making them versatile in diverse environments. By combining both volumetric calculations with spatial considerations, you will be better equipped to choose a tank size that is both functional and efficient. Moreover, think long-term; assess future needs and potential expansion to avoid the inconvenience and cost of upgrading your system too soon. Proper sizing not only ensures efficiency but also enhances the longevity of your water storage system, ultimately benefiting your overall operation.

This chart illustrates the number of modular water tanks required based on varying tank capacities. As the capacity increases, the number of tanks needed decreases, allowing for efficient space and resource management.

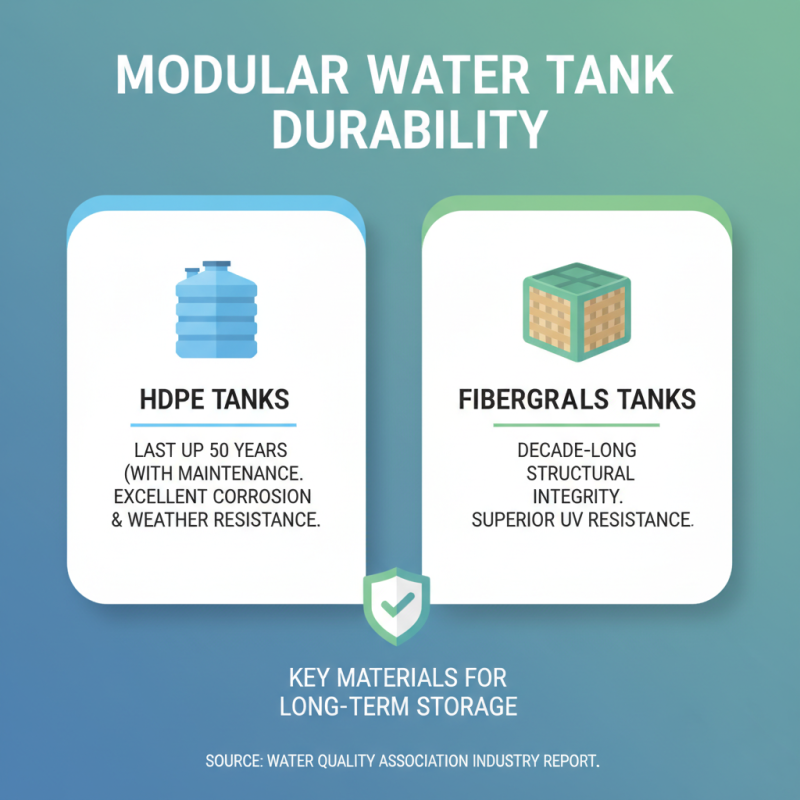

When evaluating the durability and longevity of modular water tanks, the choice of materials is paramount. High-density polyethylene (HDPE) and fiberglass are among the leading materials favored in the industry for their resistance to corrosion and extreme weather conditions. According to a recent industry report from the Water Quality Association, tanks constructed of HDPE can last up to 50 years when properly maintained, making them a reliable choice for long-term water storage solutions. Furthermore, fiberglass tanks boast superior UV resistance and have been shown to maintain structural integrity over decades, further solidifying their place as a durable option.

Additionally, understanding the environmental impact of materials is crucial. According to the Environmental Protection Agency, the lifecycle analysis of various tank materials indicates that both HDPE and fiberglass have lower environmental footprints in terms of energy consumption during production and the recycling potential at the end of their life cycle. Beyond initial material selection, proper maintenance is essential to ensure longevity; regular inspections and prompt repairs can prevent minor issues from becoming major problems. A proactive approach to maintenance, coupled with high-quality materials, is the best strategy to maximize the lifespan and efficiency of any water tank system.

When it comes to maintaining modular water tanks, implementing key maintenance practices is crucial for prolonging the lifespan of your water system. According to industry reports, regular inspections can reduce maintenance costs by up to 30%, highlighting the importance of proactive care. Regularly checking for leaks, ensuring secure fittings, and monitoring water quality can help detect issues before they escalate. It’s advisable to schedule systematic maintenance at least twice a year, focusing on cleaning and servicing key components such as valves and filters.

Another essential practice involves monitoring the structural integrity of the tank itself. A report by the Water Environment Federation indicates that nearly 20% of municipal water systems face challenges due to corrosion and deterioration of their tanks. By employing corrosion-resistant materials and applying protective coatings, water system operators can significantly extend the life of their tanks. Additionally, maintaining optimal water levels and ensuring proper drainage can mitigate pressure-related damage, thereby enhancing system reliability. Training staff in these practices can further ensure that maintenance is conducted effectively, ultimately leading to improved performance and longevity of your modular water tank system.

When considering an investment in modular water tanks, conducting a thorough cost-benefit analysis is paramount. These systems not only offer scalable solutions for various water storage needs but also maximize efficiency by reducing operational costs over time. The initial investment may seem substantial, but the long-term savings on water bills and maintenance can significantly outweigh upfront expenses. Additionally, modular tanks can be customized to fit specific requirements, making them a versatile option for different settings, from residential properties to large commercial facilities.

To ensure you make the most of your modular water tank system, consider these essential tips. First, assess your water storage needs by evaluating your daily consumption patterns; this will help you select an appropriate tank size. Second, prioritize quality materials in your tank selection to enhance durability and longevity. Lastly, regular maintenance is key—schedule periodic inspections and cleanings to prevent any long-term issues that could disrupt your water supply. By following these tips, you can optimize the efficiency and performance of your modular water tank system while ensuring it remains a valuable asset for your water management strategy.

| Feature | Description | Benefits | Cost Range (USD) | Maintenance Frequency |

|---|---|---|---|---|

| Storage Capacity | Available in various sizes (e.g., 500-10,000 liters) | Meets specific water needs | $500 - $5,000 | Every 6 months |

| Material Type | Options include polyethylene, fiberglass, steel | Durability against corrosion | $300 - $4,000 | Annual inspection |

| Installation | Professional installation recommended | Ensures proper setup | $1,000 - $2,500 | Upon installation |

| Maintenance | Regular checks for leaks and sediment | Ensures water quality | $100 - $500 annually | Monthly checks |

| Regulatory Compliance | Must adhere to local guidelines | Avoids legal issues | Varies by location | As needed |